Moving wide or heavy goods vehicles is never straightforward. When your cargo exceeds legal measurements, strict UK rules apply to protect both the road network and your operator licence.

Knowing the thresholds for HGV width UK limits (and what happens once you pass them), helps you stay compliant and avoid costly delays. Operators who understand how to plan, notify, and document every move are always one step ahead.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.

Definitions and thresholds for wide and abnormal loads

A vehicle becomes a “wide load” when its total width exceeds 2.9 metres. An “abnormal load” is one that weighs more than 44 tonnes, extends beyond 18.65 metres in length, or reaches over 4.95 metres in height.

These measurements apply to indivisible goods, meaning items that can’t reasonably be broken down for transport. Examples include wind turbines, bridge beams, or large construction machinery.

For standard freight, the HGV width UK limit is 2.55 metres, or 2.6 metres for refrigerated vehicles. Anything beyond this requires additional permissions and specific routes.

The UK’s haulage rules for vehicle size and load combinations are explained in our guide to lorry sizes and UK regulations. Understanding these limits is the first step toward safe and compliant abnormal load operations.

Here’s a quick summary:

| Measurement | Standard HGV limit | Abnormal load threshold |

| Width | 2.55 m (2.6 m for refrigerated) | Over 2.9 m |

| Weight | 44 tonnes (gross) | Over 44 tonnes |

| Length | 16.5 m articulated / 18.75 m drawbar | Over 18.75 m |

| Height | No statutory limit | Over 4.95 m (practical restriction) |

| Overhang | Up to 1 m front / 2 m rear | Over specified values must be marked |

Legal framework: C&U regulations, STGO, and Special Orders

Two main regulations govern abnormal load movements in the UK: the Road Vehicles (Construction & Use) Regulations 1986 and the Road Vehicles (Authorisation of Special Types) (General) Order 2003, or STGO. These define what counts as a legal HGV and when exemptions apply.

C&U regulations cover everyday haulage, while STGO applies to vehicles carrying heavier or longer indivisible loads. STGO is divided into three categories:

- Category 1: up to 50 tonnes

- Category 2: up to 80 tonnes

- Category 3: up to 150 tonnes

Each category has its own rules around notice periods, escort requirements, and operating conditions. Category 1 moves are relatively straightforward, while Category 3 operations may require overnight travel or police attendance.

Anything beyond those limits falls under a Special Order, granted by the Department for Transport. These are reserved for exceptional cases, such as major infrastructure or energy projects.

Trials of longer heavier vehicles (LHVs) highlight how wide load regulations UK continue to adapt as logistics evolves. For operators, that means staying informed about rule changes and testing programmes that could shape future road limits.

Notice requirements to police, highways, and bridge authorities

Before transporting a wide or abnormal load, operators must notify all relevant authorities. This includes the police, highway departments, and any bridge or structure owners along the chosen route.

Notification is required once the HGV width UK measurement exceeds 2.9 metres or the vehicle’s total weight goes beyond 44 tonnes. These notices allow authorities to check road safety, manage diversions, and protect public infrastructure.

When to use ESDAL and offline forms

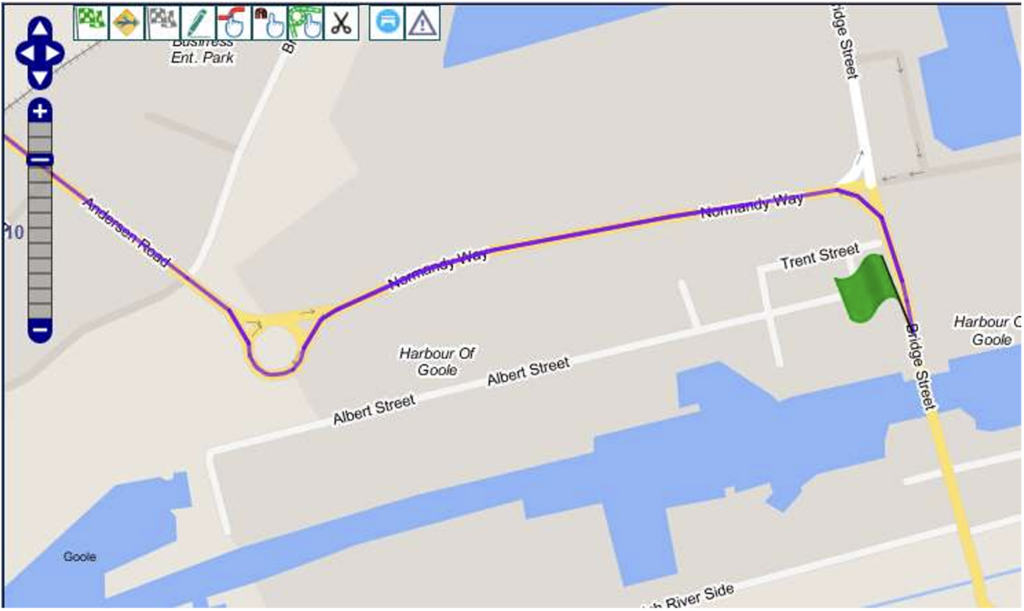

The Electronic Service Delivery for Abnormal Loads (ESDAL) platform simplifies the process by notifying all relevant bodies automatically. It ensures your documentation reaches everyone affected by your route in one submission.

Some areas still rely on traditional paper or email-based notification systems. Understanding which method applies to your route can prevent costly delays or denied movements.

Planning complex or sensitive journeys requires careful coordination between authorities, clients, and drivers. Find useful guidance for managing communication and compliance in our article on high-risk freight best practice.

Lead times and information to include

Notice periods range from two to five working days, depending on the type of move. Your notice should include vehicle dimensions, axle weights, escort information, and proposed route and travel times.

Make sure to submit accurate information, as even small errors can void approval and delay operations. Always double-check measurements before sending notifications.

Attendants, escorts, and when they are required

Attendants and escort vehicles are all-important when moving large or complex loads. They provide visibility, manage traffic, and help navigate challenging sections of the route.

Wide loads over five metres or long combinations over thirty metres typically require escort support. Escorts are also needed where visibility is limited or routes pass through urban areas.

For exceptionally large or high-risk movements, police escorts may be mandatory. Communicate early with the relevant police force to help secure availability and prevent last-minute complications.

Trained attendants assist with manual signalling and clearance checks, ensuring that every stage of the journey is properly managed. As a side note, having experienced support makes heavy haulage safer and more efficient.

Marking, lighting, and visibility for long and wide load projections

Oversized vehicles must be clearly visible to other road users. Amber beacons, red-and-yellow rear conspicuity markings and chevrons, and reflective panels are standard requirements for all abnormal load operations.

During daylight, bright flags or markers are used for any projections that extend beyond the vehicle’s main body. At night, those projections must be illuminated to remain visible from a distance.

These safety measures are consistent across wide load regulations in the UK. They aren’t just about compliance; they protect both the operator and everyone else on the road.

Vehicle choice and trailer types for abnormal indivisible loads

Choosing the right trailer setup is important for both safety and compliance. Low-loaders, extendable flatbeds, and modular trailers are all used to move indivisible loads such as large machinery or prefabricated structures.

Each design serves a purpose. For example, low-loaders help with tall cargo, while modular platforms distribute heavy weight across more axles.

Securing the wide load and documentation to carry

A well-secured load is both a safety and legal requirement. Chains, straps, and tensioners must be correctly rated and in sound condition before departure.

Operators are responsible for inspecting all securing equipment regularly. That’s mainly because damaged or worn restraints are among the most common causes of roadside penalties.

Important documents to keep on hand include the STGO order, indemnity form, and route plan, which confirm that authorities have been notified. Digital records like tachograph data are also essential for demonstrating compliance, as detailed in our guide to tachograph regulation.

Planning the move, risk assessment, timing, and roadworks

Planning an abnormal load journey involves more than plotting a route. Operators must review bridge heights, restrictions, and environmental conditions before setting off.

A written risk assessment helps identify potential issues such as poor weather, narrow junctions, or unexpected roadworks. It’s a valuable document for both safety and accountability.

Here’s a checklist for effective route planning to help you along:

- Measure vehicle height, width, and weight once fully loaded.

- Confirm bridge and tunnel clearance for the planned route.

- Submit authority notifications early.

- Schedule travel outside peak hours.

- Coordinate escort and attendant communication systems.

- Inspect securing equipment and warning lights.

Penalties, enforcement, and staying compliant

The DVSA and local police closely monitor abnormal load movements. Any failure to comply with STGO or notice requirements can lead to fines, licence suspensions, or even prosecution.

Common issues include missing authorisations, inadequate signage, or incorrect weight declarations. Be warned that enforcement teams regularly check axle loads and documentation at DVSA roadside inspections.

Compliance also supports business credibility and client trust. Many logistics contracts now include clauses that penalise subcontractors for regulatory breaches. Ongoing training and audits help operators stay up to date with legislation.

If you’re determined to become an HGV driver, be sure to explore training routes and license options beforehand.

Frequently asked questions

What counts as a wide load in the UK?

A wide load is any vehicle or combination exceeding 2.9 metres in total width. This typically includes machinery, prefabricated units, or other large industrial goods.

What is an abnormal load and how is it defined?

An abnormal load surpasses one or more of the standard threshold: 44 tonnes in weight, 18.65 metres in length, or 2.9 metres in width. These moves require prior notification and STGO approval.

What paperwork must I carry during an abnormal load move?

Operators must carry an authorisation order, indemnity form, and route plan. Tachograph data and proof of insurance should also be available for inspection.

Can I move an abnormal load at night?

Yes, but only with approval from relevant authorities. The load must be well lit, clearly marked, and may require escort support.

Do I need a risk assessment for abnormal load transport?

Yes, it’s a core part of safe and compliant operations. A risk assessment helps you prepare for route hazards and avoid unexpected issues.