Supply chain optimisation is the process of making every stage of the supply chain as efficient and cost-effective as possible. It focuses on balancing speed, quality, and flexibility while keeping costs under control.

In this guide, we’ll take you through why supply chain optimisation matters and the methods businesses use to achieve it. We’ll look at the phases involved, the key techniques, the benefits, and even the challenges you should prepare for.

What we’ll cover

Key takeaways

- Supply chain optimisation makes every stage of your network more efficient and cost-effective.

- It reduces waste, improves planning, and strengthens resilience against disruptions.

- Common methods include better inventory control, network design, and supplier collaboration in your supply chain process.

- Technology like AI, IoT, and automation is driving the future of optimisation.

Why supply chain optimisation matters

Supply chains can make or break a business. When the flow of goods and information is disrupted, the result is often late deliveries, higher expenses, and unhappy customers.

Optimisation addresses these issues by reducing waste, improving planning, and making operations more resilient. Businesses that embrace this approach can respond faster to changes in demand and stay competitive in a global market.

Phases of optimisation

Optimising the supply chain isn’t a single step; it’s a continuous process with several phases. Each phase builds on the last to create a stronger, more responsive network.

1. Design network structure and processes

The design phase sets the foundation for supply chain success. It involves decisions about warehouse locations, multimodal transport routes, and technology systems to support smooth operations.

This is also where businesses decide whether to use freight forwarders for international shipments, which can simplify customs clearance and reduce delays on cross-border routes. The goal is to create a layout that reduces transportation costs while meeting customer expectations.

2. Planning demand and inventory strategy

Planning is about forecasting demand accurately and ensuring stock levels are always aligned. Businesses analyse market data and trends to predict what customers will need and when.

Effective planning helps avoid two common problems: overstocking and stockouts. By maintaining the right balance, companies can keep costs down while ensuring product availability.

3. Execution systems and real-time control

Execution is where plans turn into action, and technology plays a vital role. Businesses use systems that provide real-time tracking, inventory monitoring, and instant alerts for any delays.

Real-time control allows for quick adjustments when something goes wrong. Whether it’s rerouting shipments or reallocating resources, these systems keep operations running smoothly.

Optimisation approaches and techniques

There’s no single formula for supply chain optimisation. Companies combine different methods based on their size, industry, and goals. Here are some common approaches.

Cost control and inventory optimisation

Managing inventory efficiently is key to reducing costs. Techniques like just-in-time delivery, demand-based replenishment, and safety stock planning help maintain lean operations.

Technology enhances these methods by using predictive analytics and automation to make decisions quickly. This approach guarantees products flow through the chain without unnecessary delays or storage costs.

Network configuration and logistics optimisation

The physical structure of a supply chain has a big impact on cost and speed. Businesses often redesign their distribution networks to improve delivery times and reduce fuel consumption.

Using a freight exchange platform makes route planning and carrier selection easier. For companies with large-scale haulage and logistics operations, this flexibility leads to better use of vehicles and capacity.

Supplier collaboration and integration

Suppliers are essential partners in an optimised supply chain. Businesses that share demand forecasts and performance data with suppliers benefit from faster response times and fewer delays.

Integration tools allow real-time communication and collaboration. This reduces errors, strengthens relationships, and helps create a supply chain that can adapt quickly to changing conditions.

Key outcomes and business benefits

When businesses invest in supply chain optimisation, the results are measurable and long-lasting. Here’s what companies can expect.

Reduced costs and higher margins

Better route planning, streamlined warehousing, and efficient use of resources reduce operating costs. These savings often lead to higher margins and improved profitability.

Lower inventory costs also free up working capital, giving businesses more financial flexibility. This allows for reinvestment in technology, staff training, and growth initiatives.

Improved quality and visibility

Quality improves naturally when every process is transparent and monitored. Businesses can identify issues earlier and resolve them before they affect customers.

Visibility across the chain also supports better decision-making. Access to real-time data helps managers respond quickly to disruptions and make informed choices about resources.

Resilience against disruptions and sustainable practices

An optimised supply chain is less vulnerable to shocks like fuel price changes, labour shortages, or extreme weather events. Businesses can adjust faster because they already have contingency plans and flexible networks.

Sustainability is another benefit. Optimised routes reduce emissions, and efficient inventory planning minimises waste. Many businesses now include environmental goals as part of their optimisation strategy.

Real‑world examples and use cases

Supply chain optimisation is not just theory; many companies have proven its impact with measurable results. Here are two case studies showing how businesses achieved success.

Toyota’s just-in-time production system

Toyota revolutionised supply chain optimisation with its just-in-time production system. This method synchronises part deliveries with assembly schedules to eliminate waste and reduce storage costs.

The approach allows Toyota to maintain lean inventories without compromising production speed. By focusing on continuous improvement, the company achieves lower costs, faster response times, and higher-quality output.

This model has influenced industries worldwide and is now a benchmark for manufacturing efficiency. It demonstrates how strong supplier relationships and data-driven planning create long-term value.

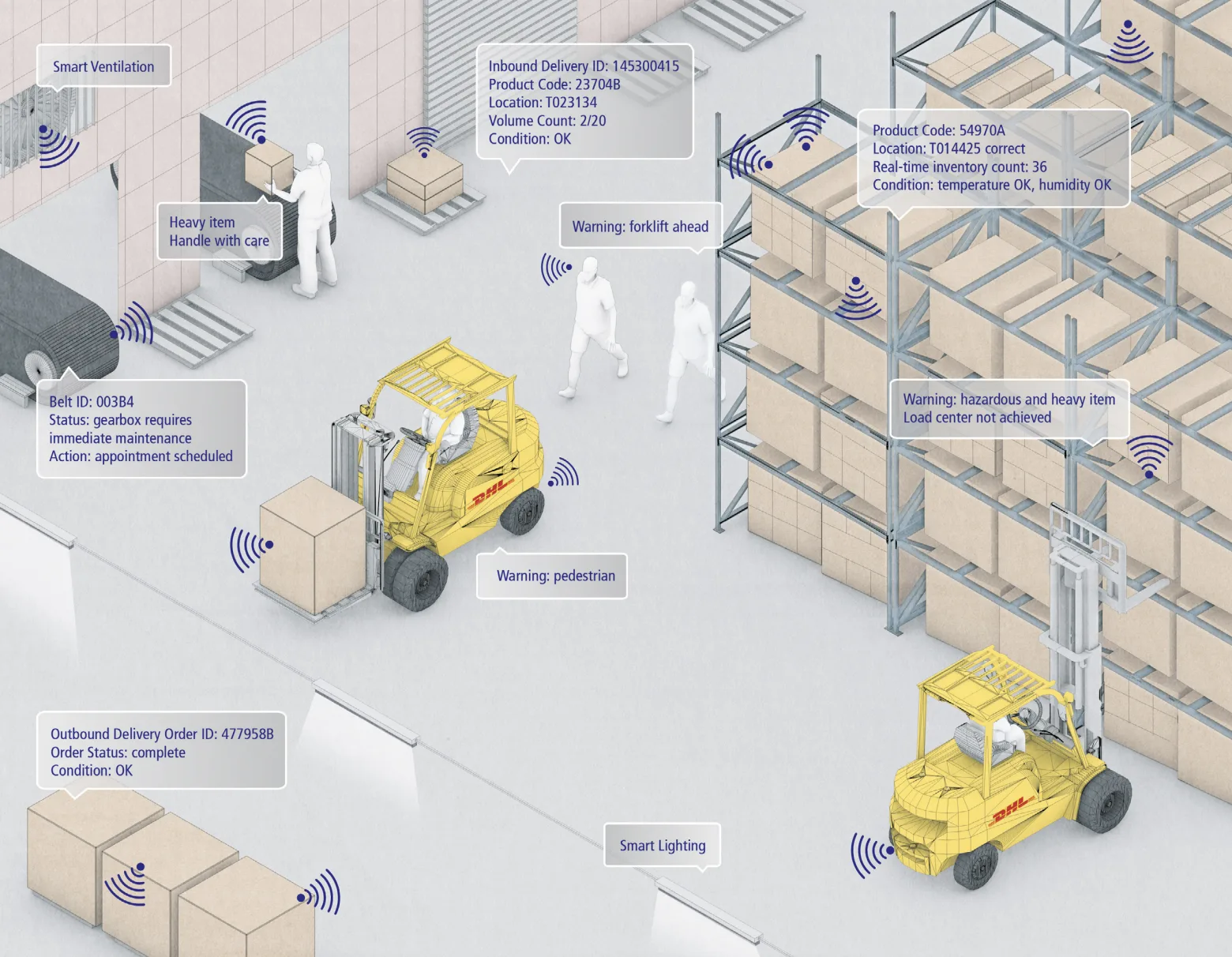

DHL’s real-time visibility tracking

DHL uses IoT-enabled sensors to monitor shipments in real time, providing instant alerts when disruptions occur. These devices track temperature, location, and humidity, which is essential for sensitive goods like pharmaceuticals.

The data collected feeds into predictive analytics tools that forecast potential delays before they impact delivery schedules. This proactive approach improves reliability and strengthens customer confidence.

DHL’s success highlights the value of digital innovation in supply chain optimisation. Businesses of any size can replicate elements of this strategy by adopting tracking solutions and integrating data for smarter decisions.

Future trends in supply chain optimisation

Technology continues to shape the future of supply chain optimisation. Here are some trends that are transforming how businesses operate.

AI-driven decision making and automation

Artificial intelligence is changing the way businesses forecast demand and manage operations. AI systems analyse huge datasets to predict trends and suggest cost-saving adjustments.

Automation improves efficiency by taking over repetitive tasks like order processing and inventory updates. This frees up staff for higher-level work and speeds up the overall process.

IoT tracking, blockchain and digital twins

IoT devices make it easy to monitor goods in real time. Businesses can track shipments, temperature-sensitive items, and vehicle locations with precision.

Blockchain adds security and transparency, which is essential for industries that rely on traceability. Digital twins (virtual models of supply chains) allow businesses to test scenarios and anticipate issues before they happen.

Challenges and common issues

Optimising a supply chain is rewarding but not without hurdles.

Here are some common challenges businesses face during the process:

- High implementation costs: Technology investments, training, and infrastructure upgrades can be expensive for smaller businesses.

- Resistance to change: Teams used to traditional processes often hesitate to adopt new tools or workflows, delaying progress.

- Poor data quality: Inaccurate or incomplete data can lead to flawed decisions and undermine optimisation efforts.

- Lack of skilled staff: Shortages in technical expertise can slow the rollout of advanced systems and automation tools.

- Failure to monitor results: Without performance tracking, businesses risk undoing the benefits of their initial improvements.

How to build a successful supply chain optimisation strategy

Creating an effective supply chain strategy takes structure and planning.

Follow these steps to build a roadmap that delivers results:

- Audit your current supply chain: Map every process from sourcing to delivery and identify weaknesses. This gives you a clear baseline for improvement.

- Set measurable goals: Decide what success looks like, such as reducing delivery times, cutting costs, or improving visibility. Clear targets keep the strategy focused.

- Prioritise actions: Start with changes that have the highest impact and are easiest to implement. This builds momentum and shows quick results.

- Invest in technology: Use tools for real-time tracking, demand forecasting, and route optimisation to improve accuracy and efficiency.

- Collaborate with partners: Share data and plans with suppliers, carriers, and customers to create a connected, agile network.

- Monitor and refine: Track performance and adjust strategies based on results. Continuous improvement is essential for long-term success.

Frequently asked questions

Which technique is used for supply chain optimisation?

Popular techniques include inventory management, route optimisation, and demand forecasting. Businesses often combine these methods with automation and AI to achieve better results.

What is the first step of supply chain optimisation?

The first step is to map your existing supply chain and highlight inefficiencies. This provides the data needed to design an effective improvement plan.

What is a supply chain in simple words?

A supply chain is the system that moves goods from suppliers to customers. It covers everything from raw materials to the final delivery point.