- How we help you

HGV safety tips: How to stay safe on UK roads

Learn practical HGV safety tips to reduce risk improve control and stay compliant on busy UK roads.

Tristan Bacon — Updated

HGV safety is about more than avoiding accidents. It’s about protecting drivers, other road users and your business from costly delays, legal action and serious harm.

From daily vehicle checks to driver wellbeing, this guide covers the practical steps that help keep HGV operations safe and compliant on UK roads.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.Why HGV safety matters for drivers, fleets and road users

HGV safety isn’t just a legal requirement. It’s essential for protecting lives, livelihoods and reputations.

For drivers, staying safe means avoiding injury, fatigue and penalties.

For fleet operators, it reduces downtime, HGV insurance costs and the risk of losing contracts or an Operator Licence.

On a wider scale, HGVs share roads with pedestrians, cyclists and other motorists, where the size and stopping distance of a lorry can turn small mistakes into serious incidents.

In areas like London, compliance is even more important. The HGV safety permit scheme, linked to the Direct Vision Standard, sets strict visibility and equipment requirements that must be met before operating legally.

Key risks for HGV drivers

Even experienced drivers face daily risks on the road. Long hours, tight schedules and unpredictable conditions can all take their toll.

Common HGV driver safety risks include fatigue from extended shifts, poor weather affecting grip and visibility, limited blind spot awareness in urban areas and load-related issues that impact vehicle handling. Distractions in the cab and pressure to meet deadlines can also lead to unsafe decisions.

Understanding these risks and performing driver risk assessments are the first steps in putting the right safety measures in place.

Vehicle safety checks, load security and compliance

Daily vehicle checks are a legal requirement and one of the most effective ways to prevent incidents. Before every journey, drivers must complete a full walkaround inspection to ensure the vehicle is roadworthy and compliant.

Checks should include tyres, lights, mirrors, brakes, fluid levels and warning systems. The tachograph must be functioning correctly, calibrated and supported by up-to-date records. Any defects must be reported and resolved before driving in line with current tachograph regulations.

Load security is just as important. Poorly secured or uneven loads can affect braking, steering and stability, increasing the risk of rollovers or collisions. Drivers should confirm weight distribution, use appropriate restraints and recheck loads at stops to ensure nothing has shifted.

These checks form a key part of roadside inspections carried out by bodies such as the Driver and Vehicle Standards Agency, and failures can result in prohibitions, fines and delays.

Safe driving techniques for HGV drivers

Safe HGV driving goes beyond staying within speed limits. It requires anticipation, control and constant awareness.

Drivers should allow extra stopping distance, brake smoothly and plan well ahead to avoid sudden manoeuvres. Sharp turns and harsh acceleration increase the risk of instability, particularly with heavy or uneven loads.

Maintaining the correct seating position and mirror setup improves visibility, while regular checks of blind spots help reduce the risk of collisions when changing lanes, turning or pulling away.

Driving safely in different environments

Driving conditions can change significantly depending on where you’re operating. Urban streets, rural roads and motorways each bring different risks, from vulnerable road users to weather and congestion.

Adapting how you drive to suit the environment is important for staying in control and reducing the risk of incidents.

Managing blind spots and vulnerable road users

HGV blind spots, especially along the nearside and rear, pose serious risks to cyclists, pedestrians and motorcyclists. Mirrors, cameras and sensors help, but frequent mirror checks and careful positioning are still essential.

Drivers should take extra care when turning, pulling away and operating in busy areas, particularly when visibility is restricted.

Urban driving risks and congestion

Urban roads bring slower speeds but higher risk. Tight junctions, heavy foot traffic and frequent stopping increase the chance of incidents.

Additional safety equipment is required under London HGV driver safety rules, and drivers should remain alert near cycle lanes, crossings and congested junctions where road users may behave unpredictably.

Driving in poor weather and challenging conditions

Rain, fog, ice and high winds all increase risk. Reduced grip, limited visibility and longer braking distances mean drivers must slow down, increase following distance and avoid sudden steering or braking.

High-sided or lightly loaded vehicles are particularly vulnerable in strong winds, especially on exposed routes and bridges.

Depot and yard safety

HGV safety doesn’t stop when the vehicle leaves the road. Depots and delivery sites present risks such as reversing incidents, collisions and slips or falls.

Drivers should follow site rules, wear appropriate PPE and respect traffic flow systems. Reversing should be carried out with a banksman whenever possible. If alone, drivers should exit the cab to assess their surroundings before manoeuvring.

Coupling and uncoupling procedures must be followed carefully, with air lines, brake connections and locks checked before departure.

Technology that improves HGV safety

Modern HGVs are increasingly supported by safety technology designed to reduce human error and improve compliance.

Telematics systems monitor driving behaviour and help fleet managers identify risk patterns. Dash cams provide valuable incident evidence, while systems such as automatic emergency braking, lane assist and electronic stability control help prevent collisions and loss of control.

Rollover prevention technology is particularly valuable for high-sided vehicles, monitoring load balance and speed in corners to reduce tipping risk.

Driver wellbeing, fatigue and breaks

Fatigue is a major contributor to HGV accidents. Long hours, poor sleep and irregular schedules all reduce alertness and reaction times.

Drivers must follow drivers’ hours rules, including mandatory breaks, and remain aware of fatigue warning signs such as lapses in concentration or microsleeps. Hydration also plays a key role, as dehydration can cause headaches, tiredness and slower reactions.

Fleet operators should actively support driver wellbeing by encouraging rest, proper nutrition and realistic scheduling.

Fleet policies, training and driver development

Clear safety policies and driver scorecards can help fleet managers monitor and maintain consistent standards across a fleet. Drivers should understand expectations around vehicle checks, safe driving and compliance.

Regular training keeps drivers up to date with regulations and best practice. This includes CPC training, defensive driving and modules focused on urban or adverse-condition driving.

Ongoing development reduces complacency, lowers incident rates and supports a stronger safety culture.

Penalties and enforcement for unsafe HGV operation

Unsafe practices carry serious consequences. Drivers may face fines, penalty points or bans depending on the offence. Vehicles found to be unroadworthy can be prohibited from operating, causing costly delays.

Repeated breaches of HGV driver safety regulations can trigger investigations by the Traffic Commissioner, putting an Operator Licence at risk. Beyond legal penalties, poor safety records damage reputation and can result in lost contracts.

Find reliable carriers and cut your costs with Haulage Exchange

Sign upFrequently asked questions

What are the most common causes of HGV accidents in the UK?

Fatigue, poor vehicle maintenance, speeding and blind spot incidents are among the most common causes. Distraction and misjudged braking distances also play a significant role.

What vehicle checks should HGV drivers complete every day?

Drivers must check tyres, brakes, lights, mirrors, indicators, fluid levels and load security before setting off. A full walkaround inspection is legally required.

How can drivers reduce blind spot risks?

Correct mirror adjustment, frequent mirror checks and the use of cameras or sensors all help reduce blind spot risks, especially in urban areas.

How can HGV drivers avoid fatigue?

Following drivers’ hours rules, taking regular breaks, staying hydrated and getting sufficient rest between shifts are essential.

What penalties apply for unsafe HGV operation?

Penalties can include fines, penalty points, vehicle prohibitions and, in serious cases, licence suspension for drivers or operators.

A well-designed driver scorecard gives fleet operators a consistent way to understand performance across individuals, vehicles, and routes. It creates a shared reference point for discussions about safety, efficiency, and compliance.

When used correctly, driver scorecards are not about constant monitoring or blame. They are a practical tool for turning everyday driving data into fair feedback, clearer expectations, and safer behaviour across your fleet.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.What a driver scorecard is and how it works

A driver scorecard is a structured performance report that tracks key driving behaviours and operational outcomes over time. It combines safety, efficiency, and compliance data into a single view that is easy for both managers and drivers to understand.

Rather than relying on isolated incidents or subjective opinions, scorecards provide a consistent evidence base. This helps operators make informed decisions and reduces the risk of bias when reviewing driver performance.

Most driver scorecards draw data from telematics systems, vehicle inspections, incident records, and policy checks. That information is then scored, weighted, and benchmarked so results can be compared fairly across drivers and operating conditions.

At its simplest, a driver scorecard answers three questions:

- How safely is the vehicle being driven?

- How efficiently is it being operated?

- How closely does the driver follow legal and company rules?

Used consistently, driver scorecards support more proactive management across haulage and logistics operations. This is especially valuable where managers cannot observe driving behaviour directly on a day-to-day basis.

Why driver scorecards matter for safety, cost and compliance

Driver behaviour sits at the centre of fleet performance. Small differences in speed control, braking, cornering, or fatigue management can affect outcomes across the business.

From a safety perspective, driver scorecards help identify patterns that often appear before incidents occur. Repeated harsh braking, speeding, or close following distances usually show up in data long before a collision or near miss is formally recorded.

From a cost perspective, smoother driving reduces fuel consumption, brake wear, tyre replacement, and unscheduled downtime. Over time, these improvements help protect margins, particularly in competitive transport markets.

Driver scorecards also help standardise expectations across complex operations. Fleets involved in intermodal transport or operating within a wider supply chain network often face varied routes, loads, and delivery pressures. Scorecards provide a consistent framework for assessing performance fairly across those differences.

Compliance is another key reason scorecards matter. They support ongoing monitoring of drivers’ hours, inspections, and policy adherence. This is particularly important for a large haulage business, where responsibility for oversight is shared across planners, managers, and depots.

The core KPIs every driver scorecard should track

Effective driver scorecards focus on a clear and manageable set of metrics. When scorecards attempt to track too many KPIs, drivers often disengage or struggle to understand what matters most.

The most reliable scorecards group driver KPI data into three core categories. This structure makes results easier to explain, compare, and act on during feedback discussions.

Safety and incident metrics

Safety KPIs focus on behaviours that increase risk on the road. These indicators are often the strongest predictors of future incidents.

Common safety metrics include:

- Speeding events relative to posted limits

- Harsh braking and rapid acceleration

- Sharp cornering or rollover risk alerts

- Following distance or tailgating alerts

- Collision, near-miss, and incident reports

Tracking trends matters more than one-off events. A single harsh brake may be unavoidable due to traffic conditions, but repeated patterns usually point to habits that need attention or support.

Over time, these metrics help fleets identify training needs, review route planning, and adjust workloads where pressure contributes to unsafe driving.

Fuel, efficiency and eco-driving metrics

Efficiency metrics show how driving style affects fuel use, emissions, and vehicle wear. These KPIs support cost control without encouraging unsafe speeds or unrealistic targets.

Typical efficiency KPIs include:

- Average fuel consumption per mile

- Idling time and engine-on idle events

- Gear use and RPM management

- Cruise control usage where applicable

In fleets operating mixed services, such as multimodal logistics, benchmarking needs to account for route type, vehicle specification, traffic conditions, and load weight. Without this context, comparisons can feel unfair and undermine trust in the scorecard.

Compliance, inspections and policy metrics

Compliance KPIs protect operator licences and reduce the risk of roadside enforcement action. They also help standardise expectations across the fleet.

Common compliance metrics include:

- Drivers’ hours infringements

- Missed or late vehicle checks

- Defect reporting accuracy

- Policy acknowledgements and training completion

- Outcomes from inspections or audits

These KPIs are particularly useful for fleets working with freight forwarders, where day-to-day visibility of driving behaviour may be limited and accountability must be clearly documented.

How to design and benchmark a fair scoring model

Fairness determines whether drivers trust a scorecard system or disengage with it. Scoring models need to reflect real operating conditions rather than ideal scenarios.

The first step is weighting. Safety-related drivers KPI measures usually carry more influence than efficiency metrics, as the consequences of unsafe behaviour are higher for drivers, the public, and the business.

The second step is benchmarking. Comparing drivers only makes sense when they operate under similar conditions. Urban delivery, regional distribution, night trunking, and long-distance motorway work each carry different risk profiles.

A simple benchmarking framework might look like this:

KPI group Weighting example Safety metrics 40–50% Compliance metrics 30–40% Efficiency metrics 20–30% Segmenting scorecards by route type, vehicle category, or operation helps drivers see the system as balanced and relevant. This approach also makes feedback conversations more constructive.

Using telematics, video and apps to power scorecards

Modern driver scorecards rely on objective data sources. Telematics systems remain central, capturing speed, braking, cornering, idling, and location data in real time.

Video telematics adds important context. Dashcam footage helps explain why events occurred and reduces disputes around scoring accuracy, particularly when drivers feel an event was unavoidable.

Mobile apps also support transparency and engagement. They allow drivers to:

- View their own scores

- Receive event alerts

- Complete vehicle checks digitally

- Access feedback or training materials

When drivers can see their own data, scorecards feel more open and consistent. This visibility often leads to better self-correction between formal reviews.

Turning scores into coaching conversations drivers trust

Data alone rarely changes behaviour. The value of driver scorecards comes from how results are discussed and acted on by managers and drivers.

Drivers respond better when feedback focuses on support rather than discipline. That requires consistent review processes, clear expectations, and respectful communication.

Feedback rhythms, training and one-to-one coaching

Short, regular check-ins are usually more effective than infrequent formal reviews. Monthly or quarterly discussions allow trends to be addressed early without creating unnecessary pressure.

Effective coaching conversations tend to:

- Start with positive behaviours

- Focus on one or two priorities

- Agree clear next steps

- Use real driving examples

Linking scorecard results to refresher training or route-specific guidance helps keep feedback practical and relevant.

Incentives, recognition and gamification that drive change

Positive reinforcement supports long-term improvement. Many fleets use recognition rather than penalties to encourage safer driving.

Examples include:

- Recognition for steady improvement

- Team-based performance targets

- Non-financial rewards such as preferred shifts

- Informal league tables within similar driver groups

These approaches work well across mixed operations involving subcontractors and directly employed drivers.

Rolling out driver scorecards across your fleet

Successful rollout depends on communication and pacing. Introducing scorecards without explanation often creates suspicion and resistance.

A phased approach works best:

- Explain why scorecards are being introduced

- Share which KPIs will be tracked and why

- Run a pilot period without formal scoring

- Gather driver feedback before finalising benchmarks

For operators starting a haulage company, early adoption of driver scorecards helps establish clear expectations before habits are formed.

Proving impact and avoiding common mistakes

Measuring success means looking beyond individual scores. Fleet-wide trends often provide clearer evidence of impact over time.

Useful indicators include:

- Fewer incidents and near misses

- Changes in fuel spend per mile

- Reduced inspection failures

- Lower downtime linked to driving behaviour

Common mistakes include inconsistent scoring, frequent KPI changes, and poor communication. Any perception of unfairness can quickly undermine trust and engagement.

What’s next: AI-driven and predictive driver scorecards

Driver scorecards are moving beyond historical reporting. AI-driven tools now analyse patterns across behaviour, routes, traffic, and conditions to predict risk.

Predictive models allow earlier intervention and more targeted coaching. Over time, scorecards are likely to become more personalised, focusing on individual risk profiles rather than uniform benchmarks.

Find reliable carriers and cut your costs with Haulage Exchange

Sign upFrequently asked questions

What KPIs should be included on a driver scorecard?

A driver scorecard should include safety, efficiency, and compliance KPIs. Common examples include speeding events, harsh braking, fuel use, drivers’ hours compliance, and vehicle check completion.

How is a driver score calculated?

A driver score is calculated by weighting different KPIs and combining them into a single score or rating band. Safety and compliance metrics usually carry more weight than efficiency measures.

How do you benchmark driver performance fairly?

Fair benchmarking groups drivers by similar routes, vehicles, and work types. Comparing like-for-like operations helps account for differences in traffic, load, and environment.

How often should driver scorecards be reviewed?

Most fleets review driver scorecards monthly or quarterly. Regular reviews help identify trends without creating unnecessary pressure from constant monitoring.

Will drivers see driver scorecards as a punishment?

Drivers are less likely to resist scorecards when the purpose is explained clearly. When used for coaching and recognition rather than discipline, scorecards tend to gain acceptance.

What role do telematics and dashcams play in driver scoring?

Telematics provides objective data on driving behaviour, while dashcams add visual context to events. Together, they create a more accurate and balanced driver KPI picture.

What are the most common mistakes when implementing driver scorecards?

Common mistakes include unclear benchmarks, inconsistent scoring, and poor communication. Rolling out scorecards without driver input often leads to mistrust.

Can small fleets benefit from driver scorecards?

Yes. Small fleets often see quicker results because communication is simpler and feedback can be more personal, making behaviour changes easier to sustain.

Certain locations across the UK have become all-important to the smooth flow of goods, offering fast access to major roads, rail links, ports, and airports. These logistics hubs handle millions of tonnes of cargo each year, keeping everything from supermarket shelves to factory lines stocked and moving.

For freight operators, choosing the right hub can impact delivery times, storage costs, and long-term growth. In this article, we’ll explore the UK’s largest and most important logistics hubs, and why they’re essential to the country’s transport network.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.What counts as a logistics hub?

A logistics hub is more than just a warehouse. It’s a location where goods are stored, sorted, and transferred between different transport modes.

These hubs connect road, rail, air or sea networks and offer 24/7 access. They also support services such as customs clearance, temperature-controlled storage, and freight consolidation.

Successful hubs tend to offer the following:

- Proximity to major motorways or ports

- Road layouts suitable for HGVs and large haulage business operations

- Intermodal transport links, such as rail freight terminals or airport access

- On-site or nearby warehousing and dispatch centres

- Reliable workforce and infrastructure support

For anyone starting a haulage company or scaling operations, location is of the utmost importance. Choosing the right hub can directly affect delivery times and operational costs.

Ranked: The UK’s largest logistics hubs

From deep-sea ports to inland freight terminals, the UK is home to several large logistics hubs supporting national and international supply chains. These sites combine warehousing, transport access, and dispatch operations to keep goods moving efficiently.

1. Midlands Golden Triangle (East Midlands)

Sources: ONS, Ordnance Survey, Esri The Golden Triangle covers an area between Birmingham, Nottingham, and Leicester. It’s known for its dense concentration of warehouses and logistics parks.

This region sits at the heart of the motorway network with the M1, M6, and M40 nearby. It also offers quick access to over 90% of the UK population within a four-hour drive.

Major sites include Magna Park, Hinckley Park and East Midlands Gateway. The latter combines rail freight, warehousing, and airport connections in one integrated site.

The Golden Triangle is ideal for fast-moving goods, retail distribution, and national supply chain networks. Its central location makes it one of the most valuable areas for multimodal logistics.

2. DIRFT (Daventry International Rail Freight Terminal)

DIRFT is one of the UK’s most advanced inland intermodal transport terminals. It sits just off the M1 in Northamptonshire, connecting road and rail networks.

This hub allows for efficient freight movement from the Channel Tunnel and major ports to inland destinations. It plays a huge role in reducing road congestion by shifting volume to rail.

DIRFT is surrounded by large warehouses and dispatch centres used by leading supermarkets and retailers. It is particularly strong in grocery logistics and time-sensitive supply chains.

The terminal is constantly expanding, too. It continues to grow as a hub for freight forwarders seeking reliability and scale.

3. Port of Felixstowe

Felixstowe is the UK’s busiest container port, handling over 4 million TEUs annually. It serves as a major entry point for goods arriving from Asia and beyond.

Its deep-water berths accommodate the world’s largest vessels. And, the port connects to inland hubs via rail and the A14, providing access to the Midlands and beyond.

Felixstowe has nearby warehousing zones and a dedicated rail terminal. It’s an important hub for international trade, especially for businesses reliant on containerised freight.

4. Port of Southampton

Southampton is a deep-sea port known for its automotive and container traffic. It’s also the UK’s second-largest container port after Felixstowe.

The port serves global shipping routes, particularly linking the UK with the Americas and the Far East. It’s a preferred choice for businesses moving high-value and time-sensitive goods.

With road and rail access to the Midlands and London, Southampton supports regional distribution. It’s also heavily used by the automotive sector for import and export.

For haulage and logistics operators focusing on global trade? Southampton is an indispensable southern gateway.

5. Port of Liverpool / Seaforth

Liverpool is the principal west coast port and a growing alternative to southern ports. The Seaforth terminal supports containerised cargo and short-sea shipping.

The port links directly to the M62 and M6, facilitating easy access to the North West and Midlands. It also offers ferry routes to Ireland and transatlantic services.

Liverpool is increasingly used by freight forwarders due to reduced congestion and improved turnaround times, and it’s a valuable link in the UK’s north-south distribution system. Plus, the surrounding area has become a logistics cluster, supporting storage and dispatch for FMCG and retail.

6. The Humber ports (Immingham, Grimsby, Hull)

The Humber ports collectively form the UK’s largest port complex by tonnage. Immingham alone handles more than 55 million tonnes per year.

These ports are very important for bulk cargo, Ro-Ro services, and offshore energy supply chains. They serve sectors such as fuels, chemicals, cars, and foodstuffs.

Road and rail access connects these ports to Yorkshire, the East Midlands, and the North – plus, The Humber is also emerging as a hub for renewable energy logistics. For large haulage business operators serving the North, the Humber offers scale and sector diversity.

7. London Gateway & Thames Freeport

London Gateway is a modern deep-sea port operated by DP World. It’s part of the Thames Freeport, which provides tax and customs incentives.

The port is supported by a vast logistics park offering on-site warehousing. It’s also rail-connected and close to the M25, allowing for rapid movement into London.

As a newer facility, London Gateway is designed for automation and efficiency, and it supports both import-heavy and e-commerce focused supply chains. This hub is ideal for businesses looking for scalable logistics in the South East.

8. Heathrow Cargo & surrounding logistics cluster

Heathrow is the UK’s largest air freight terminal, handling over 1.5 million tonnes annually. It’s essential for high-value, time-critical cargo.

Surrounding Heathrow are logistics parks, bonded warehouses, and courier hubs. This ecosystem supports fast processing and same-day dispatch.

Sectors such as pharmaceuticals, fashion, and electronics rely on air cargo. The Heathrow cluster plays a unique role in the UK’s multimodal logistics system, and for freight forwarders handling international freight, it’s an important hub.

Why these hubs dominate: location, access and infrastructure

Several factors explain why these hubs have risen to prominence. However, strategic location is the most obvious.

Many of the UK’s top hubs are situated near major motorways like the M1, M6, and M40. These allow easy north-south and east-west movement by road.

Rail links further boost intermodal capabilities. Sites like DIRFT and East Midlands Gateway, for example, demonstrate the value of combining rail freight with warehousing.

Other reasons include:

- HGV-friendly infrastructure and secure HGV parking

- Proximity to population centres or manufacturing zones

- 24/7 operational access

- Freeport or customs clearance advantages

- Local government and private sector investment

Together, these features reduce delivery times, and support large-scale operations. Plus, they also improve overall supply chain efficiency.

Regional breakdown: north, midlands, south and devolved nations

The Midlands remains the dominant inland region for logistics. Its central location supports nationwide delivery within tight timeframes.

Northern regions are seeing significant growth in warehousing and freight movement. Doncaster and Warrington are two examples of strong regional logistics centres.

In the South, ports and air hubs lead the way. Southampton, London Gateway, and Heathrow provide all-important links for international freight.

Scotland’s main logistics activity centres around Glasgow and Grangemouth. Wales has emerging logistics parks near Cardiff, while Belfast supports multimodal transport in Northern Ireland.

Emerging and rapidly growing hubs to watch

As demand grows, new hubs are gaining ground:

- Doncaster iPort: Offers road and rail connections with vast warehouse capacity.

- Teesport: Positioned for offshore, energy, and chemical logistics.

- Avonmouth (Bristol): Serving the South West with new distribution centres.

- East Midlands Gateway: Rapidly expanding hub for airport, rail, and road freight.

These locations are attracting investment due to their connectivity and available land. They’re particularly attractive to businesses seeking long-term growth outside traditional hotspots.

What sectors each hub serves

To understand the role of each logistics hub, it helps to know which industries they support. Different sectors rely on different modes of transport, storage types and distribution speeds.

Here’s a quick breakdown:

Logistics hub Main sectors Golden Triangle National retail, e-commerce, FMCG DIRFT Parcel networks, food logistics, rail freight Felixstowe Imports, manufacturing, consumer goods Southampton Automotive, containers, deep-sea routes Liverpool / Seaforth FMCG, Ireland/US exports, regional freight Humber ports Bulk transport, energy, offshore, automotive London Gateway Fast retail turnover, high-volume imports Heathrow Cargo Pharmaceuticals, electronics, luxury goods Some hubs are designed to serve a wide mix of industries. Others are highly specialised, offering temperature control, bonded storage or fast customs processing.

What this means for logistics operators and fleets

For any logistics business, location is a strategic choice. Where you base your vehicles, store goods or link up with couriers can impact your entire delivery model.

Operators with national routes benefit from basing near motorway-connected hubs. This reduces delays, improves routing and allows more flexible load planning.

Those focusing on import/export can save time and cost by using port-adjacent warehouses. Ports like Felixstowe or Liverpool are ideal for companies needing access to customs and international freight corridors.

Businesses using intermodal transport will prefer hubs with on-site rail links. These facilitate smoother transfers between long-haul and last-mile logistics.

Here are a few operational takeaways:

- Fleet planning: Hubs with good road access reduce dead mileage and allow tighter delivery windows.

- Warehouse decisions: Choosing a site near a major hub can cut lead times and support seasonal surges.

- Scalability: Emerging hubs often offer room for growth, lower rents and less congestion.

- Customer expectations: Using the right dispatch centre can help you promise next-day or same-day delivery more reliably.

- Partnerships: Many freight forwarders cluster near major hubs. Being close makes collaboration easier and more cost-effective.

Whether you’re an established firm or just starting a haulage company, hub choice matters. It affects everything from profitability to customer satisfaction.

Find reliable carriers and cut your costs with Haulage Exchange

Sign upFrequently asked questions

Which are the biggest logistics hubs in the UK by volume?

Felixstowe leads in container volume, followed by Southampton and London Gateway. Immingham handles the highest overall tonnage due to bulk and energy cargo.

Why is the Golden Triangle considered the UK’s leading logistics region?

It provides access to most of the UK within four hours and sits at the intersection of major motorways. Its dense concentration of warehouses and transport links makes it ideal for nationwide distribution.

What sectors rely most on the major logistics hubs?

Retail, automotive, pharma, e-commerce, fashion and FMCG are the biggest users. These sectors rely on fast, reliable and scalable logistics services.

What is the difference between a logistics hub and a distribution centre?

A logistics hub includes warehousing, intermodal connections and transport services in one zone. A distribution centre is typically a single facility within a wider hub.

What factors determine where new logistics hubs are built?

Transport links, land availability, labour force, and planning permissions all matter. Freeport status or tax incentives can also influence site selection.

Moving freight in 2026 is about to get a lot more complicated — and a lot more expensive if you’re not prepared.

This week’s update dives into the rules every operator needs to understand right now: from the hard limits around abnormal and wide loads, to a major government move slashing the cost of electric lorries by up to £120,000, and sweeping EU legal changes that are reshaping borders, customs and carbon costs.

We also look at what else is impacting day-to-day operations, including major motorway disruption on the M6, how AI is quietly transforming warehouses, and why January’s “Q5” period could unlock new work for prepared fleets. Let’s get into it.

⚡ £120k off electric lorries

The government has announced a major boost for fleet electrification, cutting the upfront cost of electric lorries by up to £120,000 through an expanded Plug-in Truck Grant.

Backed by £18m in new funding, the scheme supports vehicles from 4.25 tonnes right up to the heaviest HGVs, helping operators bridge the gap between diesel and electric.

The move sits within a wider £318m green freight plan and comes alongside a consultation on phasing out non-zero-emission HGV sales by 2040 — giving fleets more certainty to plan ahead.

→ See who’s eligible and how much you could save.

🚛 Abnormal loads: know the limits

Moving wide or abnormal loads isn’t just about size — it’s about planning, permissions and precision.

Once a vehicle exceeds standard width, weight, length or height limits, operators must follow strict UK rules designed to protect infrastructure, road users and operator licences.

Our latest guide breaks down the key thresholds, explains how STGO categories work, and clarifies when notifications, escorts and police involvement are required. It also covers route planning, marking and lighting, load security, and the paperwork drivers must carry.

Get it wrong and you risk delays, fines or enforcement action.

🌍 New EU freight rules hit in 2026

From mandatory digital border systems to carbon charges and tougher customs controls, 2026 marks a turning point for European road transport.

New requirements like France’s ELO logistics envelope, full ICS2 import controls, CBAM carbon costs and updated export systems are already changing how cross-border freight operates. Carriers now carry greater responsibility for data accuracy, emissions reporting and compliance — with delays and financial penalties for those unprepared.

This analysis explains what’s live, what’s coming next, and how operators should respond to stay competitive.

→ Find out what you need to prepare for now.

Also worth a read

- 📦 The post-Christmas “Q5” period can unlock new haulage opportunities, from handling returns to supporting January sales, if fleets plan ahead and adapt quickly.

- 🚧 Major disruption is expected on the M6 near Penrith as Network Rail replaces the Clifton bridge, with full motorway closures, long HGV diversions and months of ongoing works.

- 🤖 New research shows AI has moved from pilot projects to everyday warehouse operations, with most sites now using automation to boost productivity, accuracy and resilience.

- 🚔 A Scottish haulage worker has been jailed after using company vehicles to traffic large quantities of cocaine, highlighting the risks of criminal exploitation within transport operations.

Find reliable carriers and cut your costs with Haulage Exchange

Sign upMoving wide or heavy goods vehicles is never straightforward. When your cargo exceeds legal measurements, strict UK rules apply to protect both the road network and your operator licence.

Knowing the thresholds for HGV width UK limits (and what happens once you pass them), helps you stay compliant and avoid costly delays. Operators who understand how to plan, notify, and document every move are always one step ahead.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.Definitions and thresholds for wide and abnormal loads

A vehicle becomes a “wide load” when its total width exceeds 2.9 metres. An “abnormal load” is one that weighs more than 44 tonnes, extends beyond 18.65 metres in length, or reaches over 4.95 metres in height.

These measurements apply to indivisible goods, meaning items that can’t reasonably be broken down for transport. Examples include wind turbines, bridge beams, or large construction machinery.

For standard freight, the HGV width UK limit is 2.55 metres, or 2.6 metres for refrigerated vehicles. Anything beyond this requires additional permissions and specific routes.

The UK’s haulage rules for vehicle size and load combinations are explained in our guide to lorry sizes and UK regulations. Understanding these limits is the first step toward safe and compliant abnormal load operations.

Here’s a quick summary:

Measurement Standard HGV limit Abnormal load threshold Width 2.55 m (2.6 m for refrigerated) Over 2.9 m Weight 44 tonnes (gross) Over 44 tonnes Length 16.5 m articulated / 18.75 m drawbar Over 18.75 m Height No statutory limit Over 4.95 m (practical restriction) Overhang Up to 1 m front / 2 m rear Over specified values must be marked Legal framework: C&U regulations, STGO, and Special Orders

Two main regulations govern abnormal load movements in the UK: the Road Vehicles (Construction & Use) Regulations 1986 and the Road Vehicles (Authorisation of Special Types) (General) Order 2003, or STGO. These define what counts as a legal HGV and when exemptions apply.

C&U regulations cover everyday haulage, while STGO applies to vehicles carrying heavier or longer indivisible loads. STGO is divided into three categories:

- Category 1: up to 50 tonnes

- Category 2: up to 80 tonnes

- Category 3: up to 150 tonnes

Each category has its own rules around notice periods, escort requirements, and operating conditions. Category 1 moves are relatively straightforward, while Category 3 operations may require overnight travel or police attendance.

Anything beyond those limits falls under a Special Order, granted by the Department for Transport. These are reserved for exceptional cases, such as major infrastructure or energy projects.

Trials of longer heavier vehicles (LHVs) highlight how wide load regulations UK continue to adapt as logistics evolves. For operators, that means staying informed about rule changes and testing programmes that could shape future road limits.

Notice requirements to police, highways, and bridge authorities

Before transporting a wide or abnormal load, operators must notify all relevant authorities. This includes the police, highway departments, and any bridge or structure owners along the chosen route.

Notification is required once the HGV width UK measurement exceeds 2.9 metres or the vehicle’s total weight goes beyond 44 tonnes. These notices allow authorities to check road safety, manage diversions, and protect public infrastructure.

When to use ESDAL and offline forms

The Electronic Service Delivery for Abnormal Loads (ESDAL) platform simplifies the process by notifying all relevant bodies automatically. It ensures your documentation reaches everyone affected by your route in one submission.

Some areas still rely on traditional paper or email-based notification systems. Understanding which method applies to your route can prevent costly delays or denied movements.

Planning complex or sensitive journeys requires careful coordination between authorities, clients, and drivers. Find useful guidance for managing communication and compliance in our article on high-risk freight best practice.

Lead times and information to include

Notice periods range from two to five working days, depending on the type of move. Your notice should include vehicle dimensions, axle weights, escort information, and proposed route and travel times.

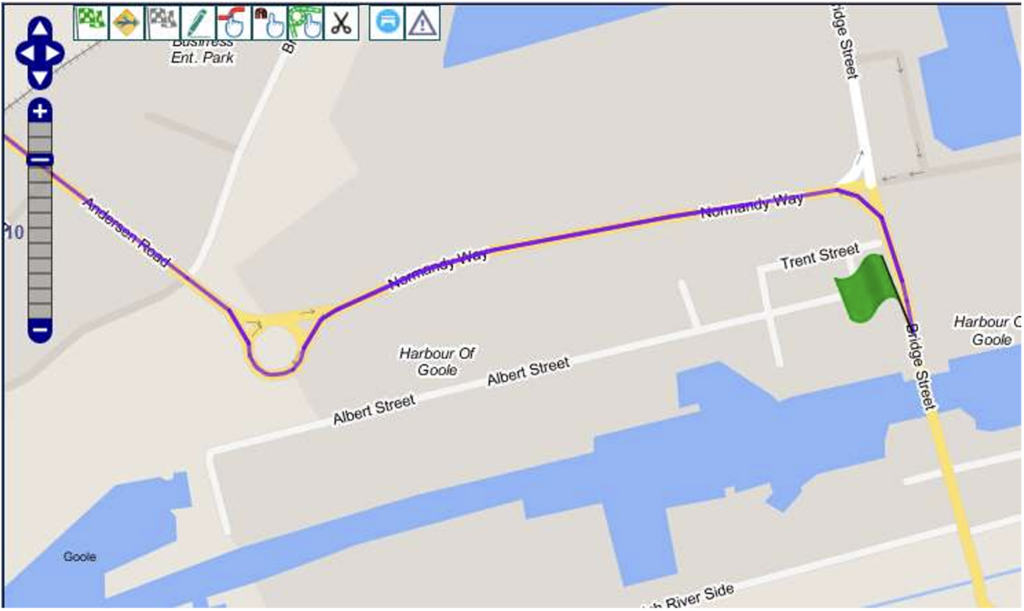

Mapping out a route on the ESDAL system. Make sure to submit accurate information, as even small errors can void approval and delay operations. Always double-check measurements before sending notifications.

Attendants, escorts, and when they are required

Attendants and escort vehicles are all-important when moving large or complex loads. They provide visibility, manage traffic, and help navigate challenging sections of the route.

Wide loads over five metres or long combinations over thirty metres typically require escort support. Escorts are also needed where visibility is limited or routes pass through urban areas.

For exceptionally large or high-risk movements, police escorts may be mandatory. Communicate early with the relevant police force to help secure availability and prevent last-minute complications.

Trained attendants assist with manual signalling and clearance checks, ensuring that every stage of the journey is properly managed. As a side note, having experienced support makes heavy haulage safer and more efficient.

Power station components being transported through Suffolk in 2023 with a police escort. Credit: Suffolk County Council. Marking, lighting, and visibility for long and wide load projections

Oversized vehicles must be clearly visible to other road users. Amber beacons, red-and-yellow rear conspicuity markings and chevrons, and reflective panels are standard requirements for all abnormal load operations.

During daylight, bright flags or markers are used for any projections that extend beyond the vehicle’s main body. At night, those projections must be illuminated to remain visible from a distance.

These safety measures are consistent across wide load regulations in the UK. They aren’t just about compliance; they protect both the operator and everyone else on the road.

An example of an escort vehicle for abnormal loads. Source: GHM Group Vehicle choice and trailer types for abnormal indivisible loads

Choosing the right trailer setup is important for both safety and compliance. Low-loaders, extendable flatbeds, and modular trailers are all used to move indivisible loads such as large machinery or prefabricated structures.

Each design serves a purpose. For example, low-loaders help with tall cargo, while modular platforms distribute heavy weight across more axles.

Securing the wide load and documentation to carry

A well-secured load is both a safety and legal requirement. Chains, straps, and tensioners must be correctly rated and in sound condition before departure.

Operators are responsible for inspecting all securing equipment regularly. That’s mainly because damaged or worn restraints are among the most common causes of roadside penalties.

Important documents to keep on hand include the STGO order, indemnity form, and route plan, which confirm that authorities have been notified. Digital records like tachograph data are also essential for demonstrating compliance, as detailed in our guide to tachograph regulation.

Planning the move, risk assessment, timing, and roadworks

Planning an abnormal load journey involves more than plotting a route. Operators must review bridge heights, restrictions, and environmental conditions before setting off.

A written risk assessment helps identify potential issues such as poor weather, narrow junctions, or unexpected roadworks. It’s a valuable document for both safety and accountability.

Here’s a checklist for effective route planning to help you along:

- Measure vehicle height, width, and weight once fully loaded.

- Confirm bridge and tunnel clearance for the planned route.

- Submit authority notifications early.

- Schedule travel outside peak hours.

- Coordinate escort and attendant communication systems.

- Inspect securing equipment and warning lights.

Penalties, enforcement, and staying compliant

The DVSA and local police closely monitor abnormal load movements. Any failure to comply with STGO or notice requirements can lead to fines, licence suspensions, or even prosecution.

Common issues include missing authorisations, inadequate signage, or incorrect weight declarations. Be warned that enforcement teams regularly check axle loads and documentation at DVSA roadside inspections.

Compliance also supports business credibility and client trust. Many logistics contracts now include clauses that penalise subcontractors for regulatory breaches. Ongoing training and audits help operators stay up to date with legislation.

If you’re determined to become an HGV driver, be sure to explore training routes and license options beforehand.

Find reliable carriers and cut your costs with Haulage Exchange

Sign upFrequently asked questions

What counts as a wide load in the UK?

A wide load is any vehicle or combination exceeding 2.9 metres in total width. This typically includes machinery, prefabricated units, or other large industrial goods.

What is an abnormal load and how is it defined?

An abnormal load surpasses one or more of the standard threshold: 44 tonnes in weight, 18.65 metres in length, or 2.9 metres in width. These moves require prior notification and STGO approval.

What paperwork must I carry during an abnormal load move?

Operators must carry an authorisation order, indemnity form, and route plan. Tachograph data and proof of insurance should also be available for inspection.

Can I move an abnormal load at night?

Yes, but only with approval from relevant authorities. The load must be well lit, clearly marked, and may require escort support.

Do I need a risk assessment for abnormal load transport?

Yes, it’s a core part of safe and compliant operations. A risk assessment helps you prepare for route hazards and avoid unexpected issues.

There’s no shortage of talk about the UK’s logistics sector, but when it comes to hard numbers, things can get a little murky. So how many haulage companies are there in the UK right now? And how do we even define them?

This guide breaks down the best available data to give you a clearer picture. We’ll explain which sources are used, how many operators exist by size and region, and why some estimates vary between datasets.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.What we counted: definition, scope, and exclusions

First, it’s important to define what we’re actually counting. Not every logistics business qualifies as a road haulage operator.

For the purposes of this guide, we’ve focused on licensed goods vehicle operators; those moving freight by road as a core service. This includes owner-drivers, small fleets, and large multi-site companies.

We’ve excluded courier companies, removal services, taxi trucks, and local delivery startups. These can be part of the broader logistics industry UK operators work in, but they fall outside standard definitions of haulage companies.

Headline number and date of estimate

As of late 2024, there were around 57,000 licensed haulage companies in the UK. This number reflects active goods vehicle operator licences.

That headline figure is based on the most up-to-date Traffic Commissioner records and data from the Office of the Traffic Commissioner (OTC). It’s important to note that licence status can change, so figures are best read as estimates.

Where the number comes from: sources and methodology

The primary source for haulage company numbers is the UK’s Office of the Traffic Commissioner. This body manages operator licences and publishes regular data.

Other inputs include analysis by trade bodies like the RHA and sector-specific reports from commercial researchers. Some third-party estimates include dormant firms or expired licences, which can inflate the numbers.

For accuracy, we’ve leaned on licence data as it’s tied to legal requirements for running HGVs. If you’re thinking of entering the industry, we’d recommend reading up on how to get an operator licence.

British haulage companies by region and devolved nations

Haulage companies UK-wide are unevenly distributed. England hosts the majority with 49,000 haulage companies, with hotspots in the Midlands, the North West, and South East.

Scotland accounts for around 5,000 firms, with a further 2,000 in Wales and 1,000 in Northern Ireland. Population density and proximity to major freight routes play a big role in these differences.

Regional clusters often reflect port access, warehouse infrastructure, and industrial presence. The East of England and the Humber region remain important for import-export operators.

Companies by size band: micro, small, medium, and large

Most UK haulier companies are small; in fact, micro-firms (with fewer than 10 staff) make up nearly 90% of the sector. These include many owner-operators and family-run firms.

Small businesses (10-49 employees) and medium-sized ones (50-249 employees) form the mid-tier. There are only a few hundred large haulage businesses with 250+ staff, but they dominate long-distance freight routes.

If you’re one of the many running or thinking of running a small haulage business, the market remains competitive but viable. Large operators like Wincanton and Eddie Stobart lead the big haulage companies in the UK.

Fleet and operator licences at a glance

According to recent data, over 430,000 HGVs are currently registered for commercial use. However, the number of operator licences is far lower.

That’s because many businesses run multiple vehicles under a single licence. Fleet size can vary widely, as some licences cover a single truck, while others manage hundreds.

Hauliers must renew their operator licence every five years. Strict rules apply, especially regarding safety, maintenance, and the financial standing of the business.

Employment snapshot: drivers and wider workforce

The UK’s haulage sector supports over 300,000 HGV drivers, though that number fluctuates with demand. Brexit, COVID-19, and working conditions have all had their impact on retention over the years.

Alongside drivers, haulage companies employ logistics planners, admin staff, compliance officers, mechanics, and warehouse workers. The wider workforce often doubles the headcount shown in driver-only statistics.

Driver recruitment remains an enduring issue. If you’re looking to expand your team, we’ve covered how to hire HGV drivers in 2025 in a separate guide.

How the total has changed in recent years

Haulage company numbers have seen modest growth since 2020. After a dip during the early pandemic, business registrations recovered steadily in 2022 and 2023.

High fuel prices and regulatory challenges caused some consolidation. However, interest in starting a logistics business remains strong, as covered in our guide to starting a haulage company.

Digital platforms, flexible contracts, and the rise of last-mile delivery all played a role in reshaping the market. So has the post-Brexit landscape, which continues to impact driver supply and cross-border operations.

Challenges facing UK haulage companies

The UK haulage industry has faced one hurdle after another over the past few years. From labour shortages to regulatory confusion, here are some of the biggest challenges still impacting haulage businesses:

- Driver shortages remain a major issue: Although the crisis has eased slightly since 2021, there is still a lack of qualified HGV drivers across the UK. Older drivers are retiring, and not enough younger recruits are joining the industry.

- Fuel costs continue to put pressure on margins: Haulage companies are heavily impacted by rising diesel prices, especially smaller firms with tighter budgets. Fuel accounts for one of the largest overheads in the business.

- Regulations and Brexit red tape make cross-border work harder: Since Brexit, companies operating across the EU-UK border face more paperwork, customs delays, and compliance costs. This especially affects businesses that rely on just-in-time deliveries.

- Low rates and high competition squeeze small operators: Many small haulage firms find themselves undercut by larger competitors or online marketplaces. As a result, they’re often forced to take contracts with razor-thin profit margins.

- Warehouse backlogs and port delays are ongoing: Delays at ports like Felixstowe and congestion at major distribution centres slow down the supply chain. This affects delivery times and increases idle time for drivers.

- Urban emission zones are expanding: London’s ULEZ and similar schemes in other cities are forcing hauliers to upgrade fleets to cleaner vehicles. That comes at a high cost, especially for older companies with non-compliant lorries.

Why estimates vary and how to compare datasets

You might see different figures depending on the source. That’s partly because of differing definitions; some include all logistics firms, while others count only those with valid operator licences.

Government data tends to be more conservative. Industry groups may include expired or dormant registrations to show sector size.

To compare properly, check whether the number reflects registered companies, active licences, or VAT-registered logistics firms. Also note the timeframe, as annual updates can lag behind real-time changes.

Find reliable carriers and cut your costs with Haulage Exchange

Book a demoFrequently asked questions

Are couriers and removals businesses included?

No, unless they hold a goods vehicle operator licence and primarily move freight. Couriers often fall into a separate category under light goods vehicles.

Why do estimates vary between sources?

Different datasets use different criteria. Some count all VAT-registered businesses under freight categories, while others rely on licensing data.

What’s the typical size of a UK haulage firm?

Most British haulage companies are small, with just one or two vehicles. Owner-drivers and family-run firms still make up the backbone of the sector.

How many vehicles per company on average?

It varies, but most UK haulage companies run fewer than five vehicles. Only large operators push into the 50+ range.

Are owner-drivers counted as companies?

Yes, if they hold an operator licence and operate commercially. Many micro-firms in the UK haulage industry are made up of just one person.

The UK’s logistics sector is booming, and with growth comes opportunity. Whether you’re driving freight, directing fleets or managing multi-channel supply chains, logistics offers a wide range of high-paying roles for skilled professionals.

In this guide, we’ll break down the top-paying logistics jobs in the UK, explore why certain roles command higher salaries, and show you what qualifications, experience and specialisations can help you earn more.

From coach driver salary ranges to strategic supply chain leadership, we’ll cover the full spectrum of roles in today’s logistics industry.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.What logistics covers and why certain roles pay more

Logistics covers everything from transportation and warehousing to supply chain strategy, procurement and analytics. Pay scales rise quickly as roles become more strategic, tech-driven or require high compliance and planning expertise.

Specialised logistics jobs like customs management, cold chain logistics, and transport analytics tend to attract higher salaries. That’s because these roles demand deep knowledge, certifications, and experience that help businesses run efficiently and legally.

Some roles also involve greater risk, decision-making authority, or oversight of important national infrastructure. These added responsibilities often translate directly into higher compensation.

Salary snapshot for top logistics roles in the UK

Here’s a look at the average salary ranges across the UK logistics industry:

Role Average Pay (UK) Senior Band (London/Strategic) Coach Driver £27,000 – £36,000 £38,000+ Supply Chain Director £85,000 – £120,000 £130,000+ Logistics Manager £45,000 – £65,000 £70,000+ Transportation Manager £40,000 – £60,000 £65,000+ Warehouse & Ops Manager £35,000 – £55,000 £60,000+ Procurement Manager £45,000 – £70,000 £80,000+ Customs Compliance Manager £50,000 – £75,000 £85,000+ Logistics jobs with strategy, compliance or network responsibilities offer the most earning potential. Sector and region matter too – coach driver salary UK data shows earnings peak around London, airports and major hubs.

Top high-pay roles in logistics

The logistics sector includes a wide range of roles, but some stand out for their earning potential. These positions often involve strategic oversight, high responsibility or specialist knowledge that’s in short supply.

Chief or director of supply chain

These senior professionals oversee entire supply chains from sourcing to delivery. They handle large budgets, high-pressure decisions and international logistics strategy.

Salaries rise quickly for those leading multi-site or international operations. Many come from backgrounds in procurement or distribution before stepping into this leadership role.

Supply chain manager

They coordinate production, inventory, transport and procurement operations. Experienced managers can rise into six-figure roles with cross-border or multi-sector responsibilities.

Industries like manufacturing, defence and retail offer high salaries at this level. Many managers pursue certifications like CILT to boost earnings.

They also play an important role in sustainability and cost control, often tasked with implementing greener transport options. As supply chains grow more complex post-Brexit, demand for experienced managers has increased across the UK.

Logistics or distribution manager

These logistics jobs manage warehouse teams, last-mile delivery and route optimisation. Pay increases significantly with scale, larger fleets, automated systems and complex delivery networks.

In e-commerce or 3PL sectors, bonuses and retention packages are common. Management software and people leadership are essential skills.

These managers often handle night shifts, cross-dock operations and returns logistics. Retailers and third-party providers rely on them to reduce delays and streamline delivery performance.

Transportation manager

This logistics job involves overseeing vehicle operations, HGV schedules and regulatory compliance. It’s a stepping stone to higher-paying fleet management and directorial roles.

You may also manage a team of drivers and negotiate contracts with hauliers. Those who have completed a become an HGV driver qualification often progress into these management roles.

They also guarantee compliance with driver hours, safety checks and DVSA regulations. Larger employers expect transport managers to lead digitisation and reduce fuel consumption across fleets.

Supply chain or logistics analyst

Data-focused logistics roles that analyse performance, optimise routing and reduce costs. These roles are rising fast in the logistics industry salary scale due to digitisation and sustainability efforts.

Most roles require strong Excel, SQL or ERP software skills. They often lead into planning or network design jobs.

Analysts are also responsible for creating dashboards, reporting KPIs and identifying inefficiencies across supply chain networks. With more companies relying on predictive analytics, this role continues to grow in demand and value.

Warehouse and operations manager

Operations managers handle staffing, inventory, KPIs, and safety compliance. Those in large depots, especially for retail or e-commerce, see higher bonuses and logistics salary growth.

Warehouses serving online retailers operate 24/7, so flexibility and workforce management are essential. Experience with WMS software and stock accuracy targets is also a major plus.

Procurement and purchasing manager

These logistics roles focus on sourcing goods, negotiating supplier contracts and reducing spend. Strategic procurement often links to board-level decision-making, increasing pay.

Leadership in this area is covered in more detail below. This role overlaps often with customs, finance and sustainability departments.

Customs and trade compliance manager

Experts in import/export law, Incoterms and trade regulations. They’re responsible for keeping operations legal and avoiding costly fines – and their salaries reflect this responsibility.

They often work closely with freight forwarders and government bodies. This role has grown post-Brexit and is in high demand.

Coach driver salary: A key role in UK logistics

A coach driver salary in the UK typically ranges from £27,000 to £36,000, depending on experience and route type. In larger cities or with private charters and tour operators, salaries may rise beyond £38,000.

To become a coach driver, you need a PCV licence, but what is that exactly? The PCV driver meaning refers to a “Passenger Carrying Vehicle” licence, which qualifies you to drive coaches or buses professionally.

So, how much do coach drivers earn compared to other transport roles? While not as high as logistics managers, coach drivers benefit from job security and regular overtime.

Here’s a breakdown:

- Base salary: £27,000 – £36,000

- With overtime: Up to £40,000+

- Private charters or tourism: Premium rates and bonuses

Many wonder how much does a coach driver earn with extra responsibilities like route planning or training. Those additional tasks can increase pay or lead to promotions into fleet management.

High‑earning specialist roles

In the logistics industry, certain specialist functions operate at the cutting edge of the supply chain, and command premium pay as a result.

These logistics roles typically involve a combination of niche expertise, strategic influence and high accountability, pushing their salary bands above standard operations roles.

Procurement and purchasing leadership

- Salary range: £50,000 ‑ £90,000 for senior managers, with director levels from around £75,000 up to £108,000+ depending on remit.

Senior procurement officers and heads of sourcing are among the highest paid delivery jobs UK wide. Their influence on cost-saving and supplier partnerships makes them top earners.

They often report directly to finance or operations directors. Pay is highest in sectors like manufacturing and defence.

Analytics and optimisation roles

- Salary range: £30,000 ‑ £45,000 for analysts; senior optimisation or network modelling roles can reach £50,000+ in some cases.

Data science and logistics combine in these positions – think supply chain analysts or network modellers. Strong Excel, SQL and supply chain system knowledge are important.

These professionals are essential for reducing costs and improving performance. They’re also valued in green logistics or carbon reporting.

Advanced data skills let them simulate distribution models, forecast inventory trends and streamline procurement. Many companies now consider this role mission-critical for competitive advantage.

Fleet and transportation management

- Salary range: £36,000 ‑ £70,000+ depending on size of fleet and region (London/multi‑site may drive higher pay).

Fleet directors often manage dozens or hundreds of vehicles, HGV compliance, and driver strategy. These roles overlap with coach driver salary trends – with management often earning double.

Leadership, route planning software and safety compliance are core skills. This role requires balancing operational efficiency with driver satisfaction.

Fleet managers also oversee vehicle acquisition, HGV insurance, servicing, and emissions compliance. Those operating across multiple depots can earn significantly more due to the complexity involved.

Specialisations with premium pay

Some areas of logistics require rare technical skills, high compliance standards, or advanced planning capabilities, and the pay reflects that.

These specialisations are needed for high-stakes operations and often lead to some of the best salaries in the industry.

Cold chain logistics

- Salary range: £45,000 – £70,000+

Cold chain logistics specialists make sure temperature-sensitive products (like vaccines or fresh food) stay within tight limits across the supply chain. Mistakes can cause catastrophic losses, making this a high-pressure, high-reward field.

Customs compliance

- Salary range: £50,000 – £85,000+

These managers handle cross-border documentation, tax rules and regulatory filings. Since Brexit, demand has surged in freight, e-commerce and global logistics sectors.

Network planning and logistics engineering

- Salary range: £50,000 – £80,000+

Network planners optimise where to place warehouses, how to route deliveries and how to reduce costs. They use modelling software and work closely with procurement and operations teams.

Career progression pathways in logistics

You don’t need to start at the top to reach high-paying logistics jobs. Many professionals move up from warehouse assistant to team lead, transport planner and eventually logistics manager.

Important steps include getting certifications, learning logistics software and moving into analytical or supervisory roles. With effort, it’s possible to move from entry-level operations into high-earning supply chain careers.

Those looking to switch logistics roles entirely can also explore how to start a freight forwarding company. These entrepreneurs often earn six-figure incomes.

Many start as admin assistants or route planners before specialising. With digital transformation accelerating, gaining software skills is often a faster route to higher pay than traditional pathways.

How to qualify: skills, certifications and experience

You don’t always need a degree to succeed in logistics. However, many high-paying logistics jobs require:

- Certifications: CILT UK, CPC, Lean Six Sigma, APICS

- Experience: Multi-site, international or regulated environments

- Skills: Data analysis, procurement negotiation, project management, HGV compliance, leadership

For coach or HGV roles, a valid licence and clean record are must-haves. Strategic roles, on the other hand, demand leadership, communication and strong commercial awareness.

To break into the field, start with entry-level logistics roles and work your way up. Logistics careers reward long-term development, hands-on knowledge and technical growth.

Find reliable carriers and cut your costs with Haulage Exchange

Sign upFrequently asked questions

Which logistics jobs pay the most in the UK?

Director-level roles like Supply Chain Director, Procurement Head, and Customs Compliance Manager top the list. These jobs carry high responsibility, strategic oversight and often multinational complexity.

Do I need a degree or will certifications and experience be enough?

You can progress without a degree, especially in operations or transport roles. Certifications like CILT, CPC or Six Sigma are widely accepted and often more practical.

Which industries offer premium pay for logistics roles?

Sectors like pharmaceuticals, defence, cold-chain logistics and e-commerce offer the highest pay. These industries deal with sensitive, high-value or fast-moving products.

Is London pay higher than the rest of the UK?

Yes – logistics salaries in London and major port hubs like Felixstowe or Southampton are typically higher. This reflects both demand and cost of living.

What skills move candidates into higher-pay bands?

Data analysis, compliance, negotiation and software expertise are in demand. Employers also value leadership, risk management and sustainability insight.

Which certifications help most for senior roles?

The most recognised are CILT (Chartered Institute of Logistics and Transport), Lean Six Sigma, and APICS CPIM. CPC is also all-important for transport and fleet-related leadership.

Can I move from warehouse operations into a higher-paying supply chain role?

Yes, many start as warehouse managers and move into analyst, procurement or logistics planning positions. Upskilling with software and analytics training helps that shift.

If you’re exploring a driving career or researching licence categories, you’ve probably come across the terms HGV and LGV. These acronyms cause plenty of confusion, especially when they seem to refer to the same type of vehicle.

In this guide, we’ll unpack the real HGV and LGV meaning, explains UK licence categories, and clears up the most common myths. Whether you’re planning to become an HGV driver or just trying to understand the differences, we’ll help you decode the terminology.

What we’ll cover

Fleets, bookings, subcontractors, compliance & payments.

With HX, you can manage them all in one place.What HGV and LGV mean today

Despite the different names, HGV and LGV now mean exactly the same thing in the UK. Both refer to vehicles over 3.5 tonnes used for commercial freight or heavy goods transport.

What does LGV stand for? LGV technically stands for ‘Large Goods Vehicle,’ not ‘Light Goods Vehicle’ as many assume, and this modern definition aligns with EU regulations that classify commercial goods vehicles by weight.

It’s important to note that many industry professionals still use both terms interchangeably. When searching for jobs, training, or legal information, you may see both HGV and LGV used in the same context, even though they legally refer to the same vehicle category.Why the terms changed in 1992

Before 1992, LGV meant Light Goods Vehicle, generally covering vans under 3.5 tonnes. HGV, on the other hand, was used for anything over that threshold.

After aligning with European directives, the UK updated its classifications. LGV was redefined to mean Large Goods Vehicle, and this brought it in line with the existing HGV category.

That means HGV and LGV now refer to the same group of heavier commercial vehicles, regardless of the brand of lorry. Despite the shift, the outdated meaning of LGV (as ‘light’) still creates misunderstanding today.

Common misconceptions about ‘Light Goods Vehicle’

Many people, including job seekers and even some employers, still think LGV refers to courier vans or small trucks under 3.5 tonnes. This misunderstanding persists in part due to the historical usage of LGV pre-1992.

In reality, vans under 3.5 tonnes fall into an entirely different licensing category. They’re often referred to as Category B vehicles, the same as standard cars.

If you’re looking at job ads or training courses and see ‘LGV,’ always check the context. Most of the time, LGV will mean the same thing as HGV: a vehicle above 3.5 tonnes.

Licence categories explained

There are several UK driving licence categories related to HGV vs LGV vehicles. These are determined by the vehicle’s weight and configuration.

Understanding the differences between them helps you figure out which type of lorry you can legally operate. Plus, it will also help you glean what kind of training you’ll need.

Category C (rigid lorries: up to 32 tonnes)

Category C licences allow you to drive large rigid-body vehicles over 3.5 tonnes, with a maximum authorised mass (MAM) of up to 32 tonnes.

These vehicles have a fixed cab and trailer, meaning they aren’t articulated. They’re commonly used for local deliveries and are often referred to in Class 2 terminology.

Category C+E (articulated lorries: up to 44 tonnes)

Category C+E licences allow you to drive articulated lorries, which have separate cab and trailer sections. These are the largest legal lorries in the UK, with weights up to 44 tonnes.

This licence is often considered the highest tier and opens the door to long-distance and high-capacity haulage jobs. You must first pass Category C before upgrading to C+E.

Category C1 (3.5–7.5 tonnes)

Category C1 lets you drive medium-sized vehicles between 3.5 and 7.5 tonnes. This licence is common for delivery drivers or specialist transport jobs such as horseboxes or ambulances.

If you passed your car test before 1997, you might already have this category included by default on your licence. A valuable perk, to be sure.

Class 1 and Class 2 vs modern categories

The terms Class 1 and Class 2 are still widely used in job descriptions, training centres, and even on fleet management sites. But these terms don’t appear on your driving licence.

They correspond to the current categories as follows:

- Class 2 = Category C (rigid lorries)

- Class 1 = Category C+E (articulated lorries

Although they’re technically outdated, Class 1 and Class 2 remain industry shorthand. So if you’re browsing training options or trying to become an HGV driver, be aware of both sets of terms.

Which licence do you need for different vehicle weights?

Here’s a quick breakdown to help you understand the weight ranges and the right licence to match:

Vehicle Type Weight Range Required Licence Van or pickup Up to 3.5 tonnes Category B Medium lorry 3.5 to 7.5 tonnes Category C1 Large rigid lorry Over 7.5 tonnes Category C Articulated lorry Up to 44 tonnes Category C+E Looking for more specific size thresholds and regulations? See our full guide on lorry sizes for more details.

How to qualify: medical, theory, practical and driver CPC

To drive HGV and LGV vehicles professionally, you’ll need more than just a licence. There’s a step-by-step process to qualify.

First, you’ll complete a medical exam to check for fitness to drive. Then you’ll need to apply for a provisional entitlement.

Next comes the theory test, which includes hazard perception and multiple-choice questions. Once you’ve passed, you can book your practical driving test for the appropriate category.

Finally, professional drivers must also complete Driver CPC (Certificate of Professional Competence) modules.

Typical costs to train and get licensed

Costs vary depending on the licence category and training provider, but here are general estimates:

- Medical test: £50–£100

- Theory test: £37

- Training course: £1,200–£2,000+

- Driver CPC: Around £300–£400

Some employers cover part of the cost for new drivers. Others offer apprenticeships or schemes to help reduce the financial burden.

Career paths for qualified HGV/LGV drivers

With an HGV or LGV licence, you can unlock a wide range of transport careers. Many start in local delivery or regional transport, then progress into higher-paying long-haul roles.

Others choose specialised fields like hazardous materials, refrigerated transport, or even international haulage. The category you’re licensed for will influence the roles available.

Outside the UK: How other regions label heavy vehicles

In the EU, the term LGV (Large Goods Vehicle) is used more often than HGV. It reflects the same categories but avoids the confusion with ‘light’ goods.

In the US, they use the term commercial motor vehicle (CMV) and classify trucks by class numbers: Class 7 and Class 8 being most similar to the UK’s HGVs. It’s helpful to be aware of these differences if you plan to work abroad or with international fleets.

Why job ads and training pages still use both terms